A guide to car engine parts and their functions

The engine is the center of the car. It produces the power needed to spin the wheels and run the car. How fast you can go depends on the engine capacity. Selecting the right components is crucial to assembling an engine that will last and perform well. The parts must handle the stress, heat, and high pressure for the engine to run smoothly. Weakness in any part may result in engine failure.

What is an engine?

Car engine basics

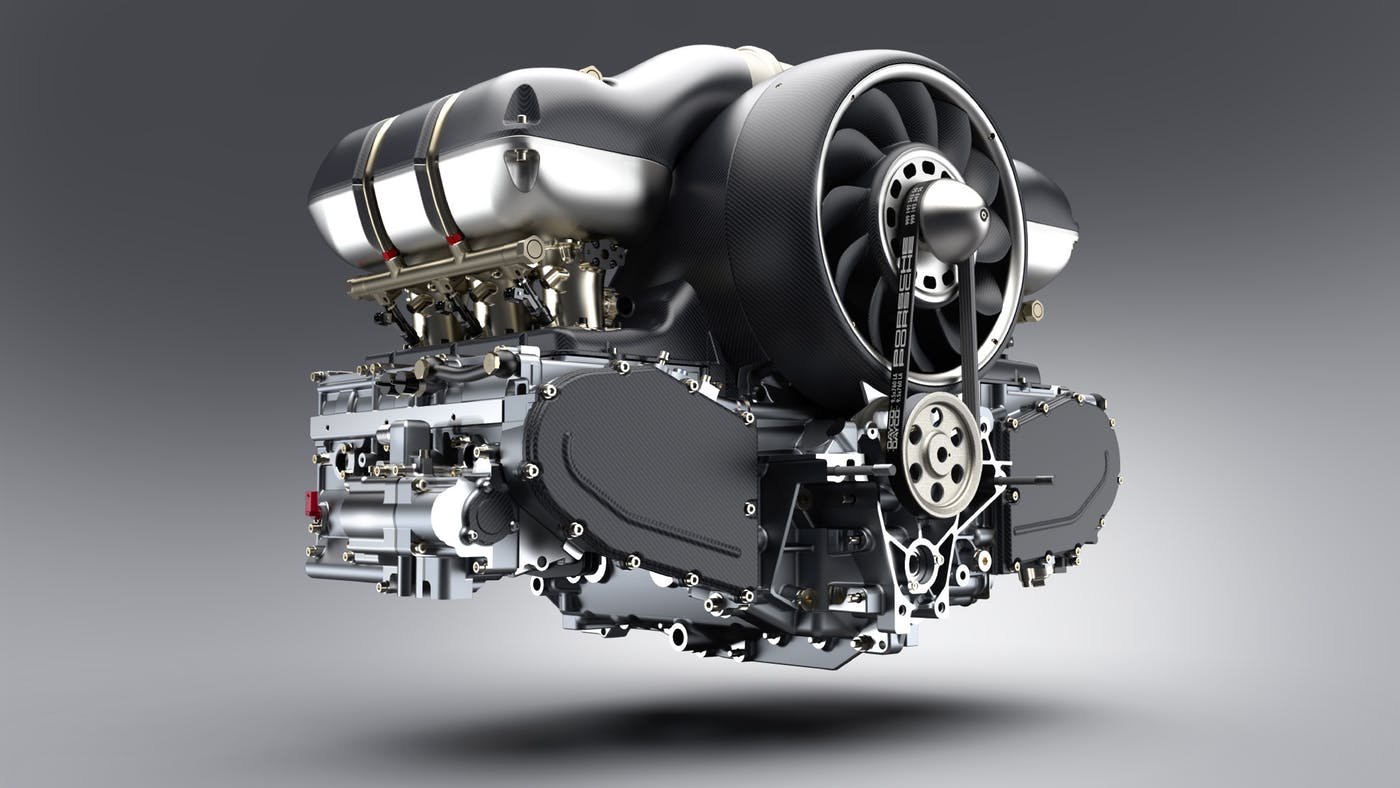

Photo on carfromjapan.com

An engine is any equipment that converts one form of energy into mechanical energy. Heat engines combust fuel to create heat which is then used to generate the force that moves the car. Electric motor engines convert electricity into mechanical motion; pneumatic motors use compressed air while clockwork motors harness elastic energy. In the automotive industry heat and electric motors are most commonly used engine types although developments are being made to make use of pneumatic motors.

Types of engines

In the automotive industry, the engine refers tao the heart of the car. The two major categories of engines

External combustion

In an external combustion motor, the fuel is heated outside the engine. The heat is used to convert water or a low boiling fluid into steam which in turn rotates a turbine. This engine type can use solid, liquid or gas fuel types and are usually used in locomotives, or ships. An excellent example of this kind of engine is a steam engine.

Internal combustion

In this engine, the fuel combustion happens inside the engine itself. When the fuel burns in the engine cylinder, high temperatures, and pressure are generated. This high pressure exerts a force on the pistons which is used to rotate the wheels. These engines can only use gases or volatile fuels like petrol and diesel. Under internal combustion, there are many types of engines. These can be classified as follows:

- According to the number of strokes it takes to turn the crankshaft – they can either be two-stroke, four-stroke, or two-and-four stroke which combines both.

- According to the design of the engine – they can be a reciprocating engine also known as a piston engine, or a rotary engine is also known as a Wankel engine.

- According to the fuel type used – the engine can either be a diesel, petrol, gas or electric powered one.

- According to the ignition method – there can either be started by spark ignition or compression ignition.

- According to the cylinders present in the engine – they can be single or multi-cylinder engines.

- According to the way the cylinders are arranged in the engine – they can either be arranged in a V-type, In-line, opposed cylinder, W-type, opposite piston or radial formation.

- According to how air gets into the engine – it can be naturally aspirated, supercharged or turbocharged.

How does it work?

We already know that an engine converts fuel into motion. This can either be through internal or external combustion. In internal combustion engines use small controlled explosions to generate the power needed to move the car. The explosive force created moves the pistons and when the energy from the first explosion is almost over another one occurs, pushing the pistons again. This happens over and over again providing the car the power it needs to run.Most engines use a 4-stroke combustion cycle to generate power. The four strokes are intake; where the intake valve opens and the piston moves down letting in air and gas, compression; the piston moves up and compresses the air and gas into a small space for a more powerful explosion, combustion; the spark plug ignites the fuel and air causing an explosion that pushes the piston back down, and exhaust; where the exhaust valve opens to release the waste gas created by the explosion. The repetition of this cycle generates the car’s power.

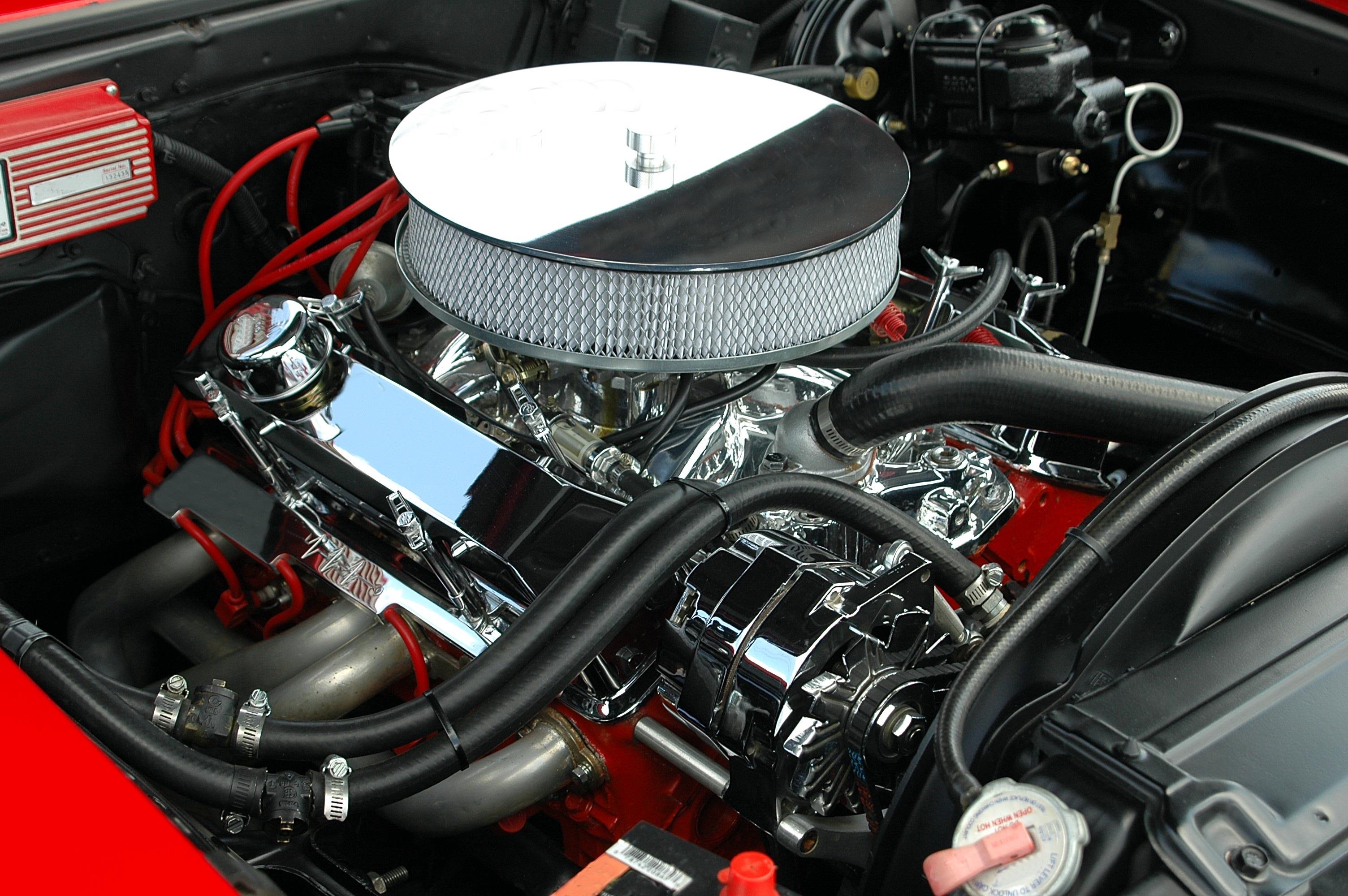

Photo on micksgarage.com

Factors to consider when picking engine components

Tips on selecting engine parts

The application of the engine – This refers to how and where the engine will be used.

- Stationary: the engine and it’s framework do not move like in generators or factory machinery

- Automotive: this refers to the use of engines to power cars. They can be petrol, diesel, gas or electric powered.

- Locomotive: these are engines used in trains mainly like steam engines.

- Marine: these are engines used to propel boats, submarines or ships. They are specially made to be used in a marine environment.

- Aircraft: these engines power planes by generating the mechanical force used to propulsion. Mainly radial and gas turbine engines are used.

The budget– How much money you have will determine the quality of the components used and what special features you can add to the engine.The durability of the parts – Opt for trusted brands that have been tested and used. Research on which brand can provide you with the best quality parts and value for your money.The type of engine – While combustion engines and electrical engines may have some similar parts in the engine other parts are engine specific.So when choosing what components to use, you must first know what engine you want or have. The capacity of the engine – The engine capacity refers to the space inside the cylinder of an engine that can accommodate the air-fuel mixture for burning. This determines its power and torque output and the mileage you can get from the fuel used. Once you have determined the capacity of the engine, you can get the right parts.

What are the components of an engine?

A list of basic car engine parts

The engine is made up of various elements that work together to produce the power needed to move the car. Below are some of the basic car engine parts despite what type of engine it is.

Engine block

This is also known as the cylinder block and is the central part of the engine. This is where the combustion of the air-fuel mixture takes place and all the other parts like the piston, connecting rods, crankshaft, etc. are bolted on. It is molded with the exact number of cylinders to be used and in what style they are to be arranged in. It also has holes for letting in water and oil, which are needed for cooling and lubrication respectively. The oil paths are narrower than the water ones.It has semi-circular seats where thrust bearings are mounted, and the crankshaft is then placed in these bearings and held in place with bearing caps which are screwed into place.

Piston

A piston is a cylindrical structure with a flat top and groves along its circumference. It moves up and down in the circular holes cut out in the engine block transmitting thrust to the connecting rod. Piston rings are placed in the groves to reduce friction as the piston moves in the engine block. It compresses the air-fuel mixture in the cylinder and converts the fuel energy into mechanical energy. This power is then transmitted to the crankshaft

Connecting rod

It joins the piston to the crankshaft and aids in the transmission of the motion and thrust of the piston to the crankshaft. It is an “I” shaped structure where the lower, smaller side is attached to the piston while the bigger end goes to the crankshaft. The piston end has a hole through which a wrist pin is placed joining the piston and the rod. The other end is made of two parts; a semi-circular journal bearing seat that goes over the crankshaft, the other part is the journal bearing cap. These two are bolted together holding the crankshaft in between them.

Crankshaft

Usually found at the bottom of the cylinder block, it is designed to convert the linear piston motion into rotational motion which moves the car’s wheels. It is made of cast iron or forged steel, for high power engines with a high crankshaft load.

Oil sump

It is also known as the crankshaft casing. It is attached to the bottom of the cylinder block and is where all the oil used to lubricate the moving parts in the block is placed. The crankshaft has small holes which spill the oil toward the pistons, to remove heat and grease the piston rings. There is a bolted hole at the bottom used to empty the oil during maintenance.

Engine head

Also known as the cylinder head. It is molded in the same shape as the engine block. It is placed on top of the block, and its function is to seal the working end of the block. It has openings that allow air in and let the exhaust out. The movement of air in and out of the gas openings in the block is controlled by the valves, which are fitted to the cylinder head. The spark plug and camshaft are also fitted onto it. It is bolted to the cylinder block with nuts and bolts with a gasket in between.

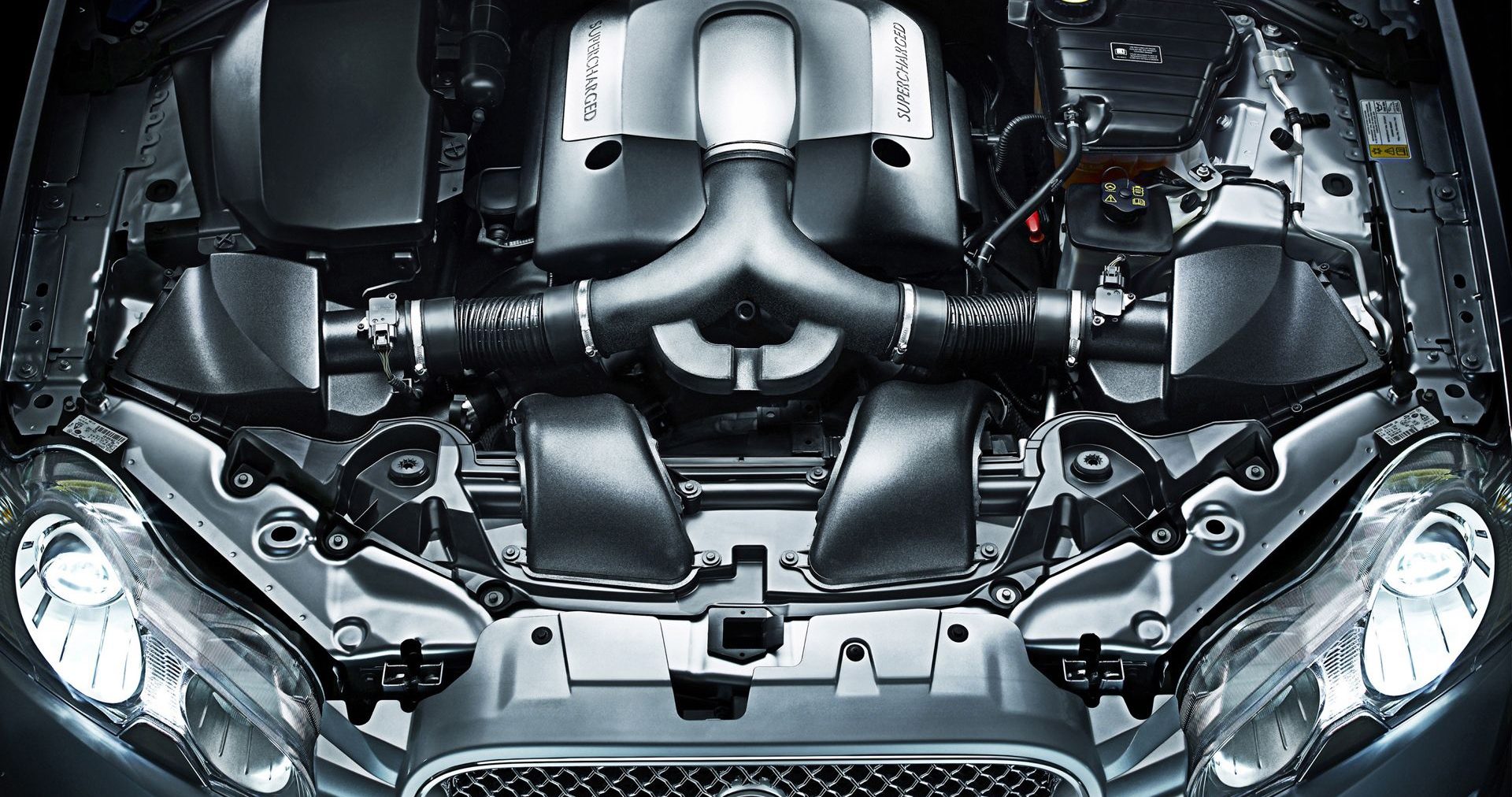

Photo on teamsls.ca

Valves

They control the air-fuel mixture movement into the engine block and the flow of exhaust gas out. They are made of a nickel-chromium-iron alloy the is resistant to high temperatures and very sturdy. A valve is typically made of two parts, the stem, and head. The head rests in a valve seat in the engine block while the stem is attached to the engine head. When the inlet and outlet valves are sealed no pressure can get in or out of the engine block, this helps maintain optimal high pressure.

Camshaft

It is either placed in or at the bottom of the cylinder head. It controls the opening and closing of the valves at the right time in a multi-cylinder engine.

Valve spring and tappet

The valve spring provides a self-returning mechanism when the valve is not being pressed down by the camshaft. The tappet supplies a smooth surface for the camshaft to press the inlet or outlet valve. The spring goes around the valve stem, and the tappet goes over them, and the camshaft is placed on top of the tappet.

Push Rod

It is used when the camshaft is at the bottom of the cylinder head. It regulates the valves through the rocker arm and camshaft

Timing belt

It transfers the motion of the gears mounted on the crankshaft, the crank-gear, to those mounted on the camshaft. The cam-gears rotate in a ratio of 2:1 to the crank-gear, this means the camshaft will have only turned once in two rotations of the crankshaft. It is made of glass-fiber or kevlar as these materials do not wear out quickly.

Spark plug

It is used in spark ignition engines to ignite the air-fuel mixture in the cylinder by producing a spark at the end of each compression stroke. The car battery powers it. It is made of titanium as it can withstand the high temperatures generated by the electricity while producing the spark.

Injector

It is used in compression ignition engines. It is fitted in the engine head and used to inject the fuel in spray form into the cylinder at the end of the compression stroke.

Gasket

It is generally a sheet-like material placed between the engine head and block. It prevents the water or oil from leaking into the cylinder or the air-fuel mixture from the cylinder from leaking out. Aluminum engine blocks are preferred to cast iron ones as they expand more when hot further compressing the gasket, increasing its workability and reducing the chances of leakage. They are made of materials like Teflon, glass-fiber, silicone, etc.

Piston rings

They reduce the friction between the piston and cylinder walls and prevent the leakage of the pressure created by burning the air-fuel mixture. They also scrap the oil from the cylinder walls spilled by the crankshaft to reduce the heat from the piston and transfer it to the cylinder walls which are water cooled.

Manifold

They are bolted on to the engine head, one for intake and another for exhaust. It is used to evenly distribute the air-fuel mixture for intake and collect all the exhaust from all the cylinders.

Piston Pin

It is also known as the gudgeon pin. It connects the piston to the connecting rod.

Engine bearings

They are used to support the moving parts of the engine. They work to reduce friction. There are two kinds of bearings used in an engine, sliding and rolling.

Turbocharger/Supercharger

These are known as forced induction systems, and they compress the air flowing into the engine boosting its power. The main contrast between a turbocharger and a supercharger is in how they are powered.

Fuel filter

It is used to screen out the dust and debris that may be present in the fuel. The contaminants could cause rapid wear and failure of the fuel pump or injectors. They also improve the performance of the engine as the fuel burns better with fewer pollutants.

Radiator

They are used to cool internal combustion engines. A liquid known as an engine coolant is pumped around the engine block where it absorbs the heat generated and then passed through the radiator to cool it and then back to the engine block

Valvetrain

It is a mechanical system that controls the valve operation in an internal combustion engine where a series of components transfer motion through the assembly. It consists of valves, pushrods, lifters, and camshafts. The configuration of valvetrains depends on the location of the camshaft, either in-block, overhead, or camless.

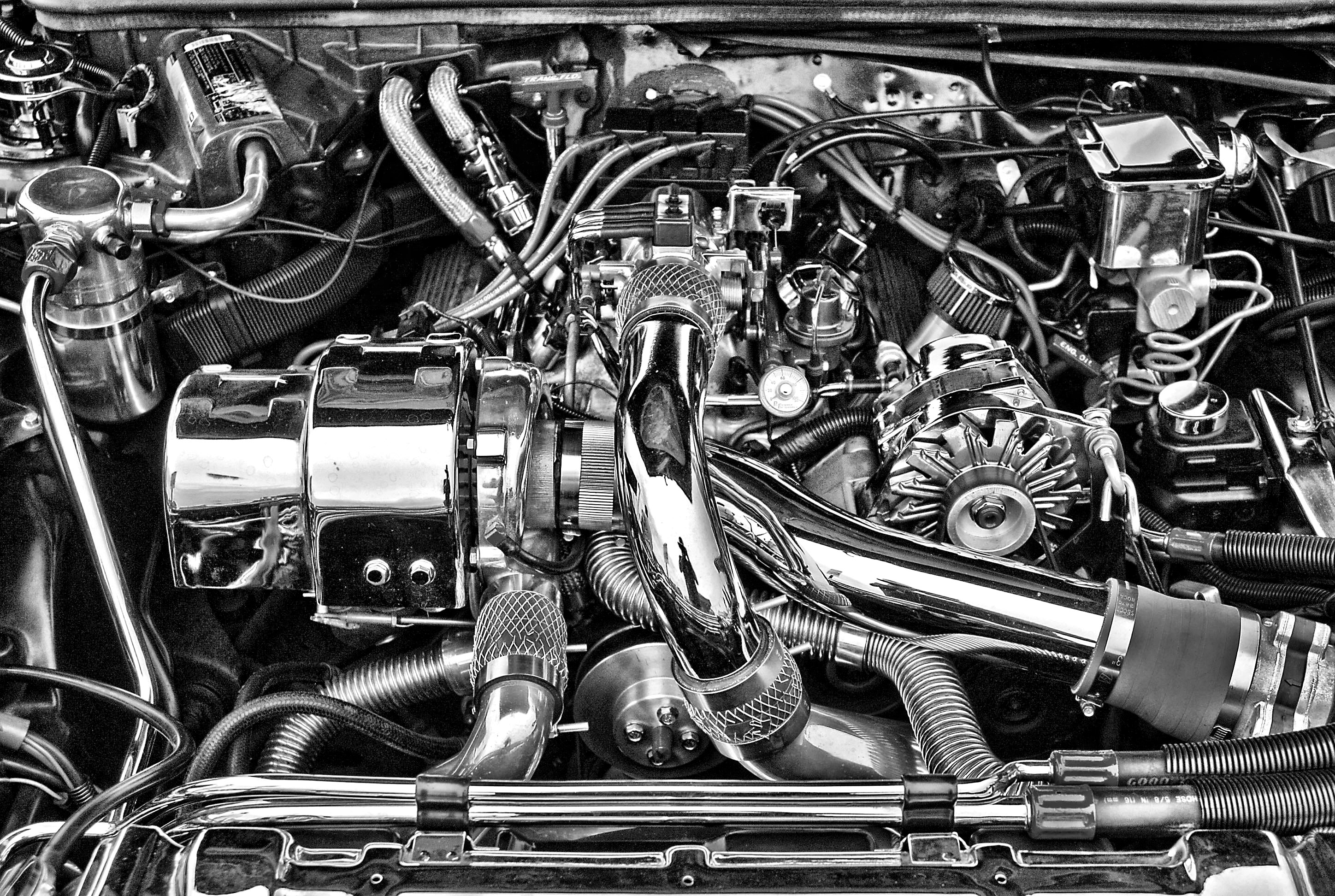

Photo on ricksmithphotos.wordpress.com

How to build an engine?

Basics to engine building

Now that you know the necessary engine components, successfully building your own engine is a matter of working carefully paying close attention to detail. When in doubt about something, do not guess, find the right answer. There are a lot of sources that have answers to the questions you may have, try going through the car manual, or contacting the maker of the part you have questions about. This will help do away with mistakes, wasted time and money.

Engine construction tips

- Choose the modifications you want that are budget-friendly, reliable and can perform well.

- Decide how your car will be driven and select the engine components accordingly.

- Before you start assembling the engine parts, make sure you are working in a clean contaminant free area. With soap and hot water clean the cylinder block and the other parts thoroughly. Microscopic dirt particles can damage the engine parts and cause failure.

- Make sure the assembly is well balanced. All the weight has to be equally distributed to avoid excess weight being thrown in the wrong direction when the engine moves.

- Micro-polish the crankshaft. These mall nicks and scratches can affect eh millage of the crank.

- Hone the cylinder block as it affects how long it will last, whether it will burn any oil and if it will reach its full potential in the stroke cycles. The pistons and rings will determine the bore size and finish.

- Deck the engine head and block to prevent blown gaskets. Completely flattening these surfaces will ensure a better tighter fit for the gasket.

- File down the piston rings to make them fit exactly in the cylinders. Most come with guidelines to let you know how much material you should remove based on the bore size and cylinder pressure.

- Placing the valves securely ensure that the pressure generated will not be lost or leaked and eases the movement from the ports to the combustion chamber.

- Double check the cylinder bores, crankshaft journals, rod journals, and deck height to ensure the right oil use, compression and clearances. For this specialized tools are needed like a bore gauge.

- Determine the right crank and rod bearings to use according to your engines service manual.

- Use a properly calibrated torque wrench to fasten the bolts in the engine.

With these in mind:

- Place the crankshaft into the engine block and secure it using bearing caps. Do not forget to properly lube the caps and the engine block as the crankshaft sits on a layer of lubricant not directly on the block.

- Place the piston rings in the right order on the pistons and connect the pistons to the crankshaft via the connecting rods.

- Next, connect the main gear to one end of the crankshaft and fasten it onto the block.

- On the engine-head attach the valves according to the formation of the cylinders in the block and attach the camshaft and the cam gears.

- Once this is done place the gasket in between the engine block and head and fasten the two parts together.

- Now using the timing belt connects the cam-gears to the crank-gears so that the rotation of the crank is transferred to the camshaft. Once you are done, place the cover onto the timing belt assembly.

- Next, attach the manifolds to the engine and the oil sump to the bottom of the block.

- Connect the spark plugs or injectors depending on the type of engine you are building. Be sure to connect them to the car’s electrical system.

- Make once you are done assembling the engine make sure to test it.